OVERVIEW OF VIETNAM PLASTIC INDUSTRY FDI INVESTMENT

According to data from the Vietnam Plastics Association (VPA), the total FDI capital into the plastics industry has consistently increased from 2020 to 2025, accounting for a significant proportion of the sector’s overall investment. Leading FDI contributors include Japan, South Korea, Thailand, and Singapore.

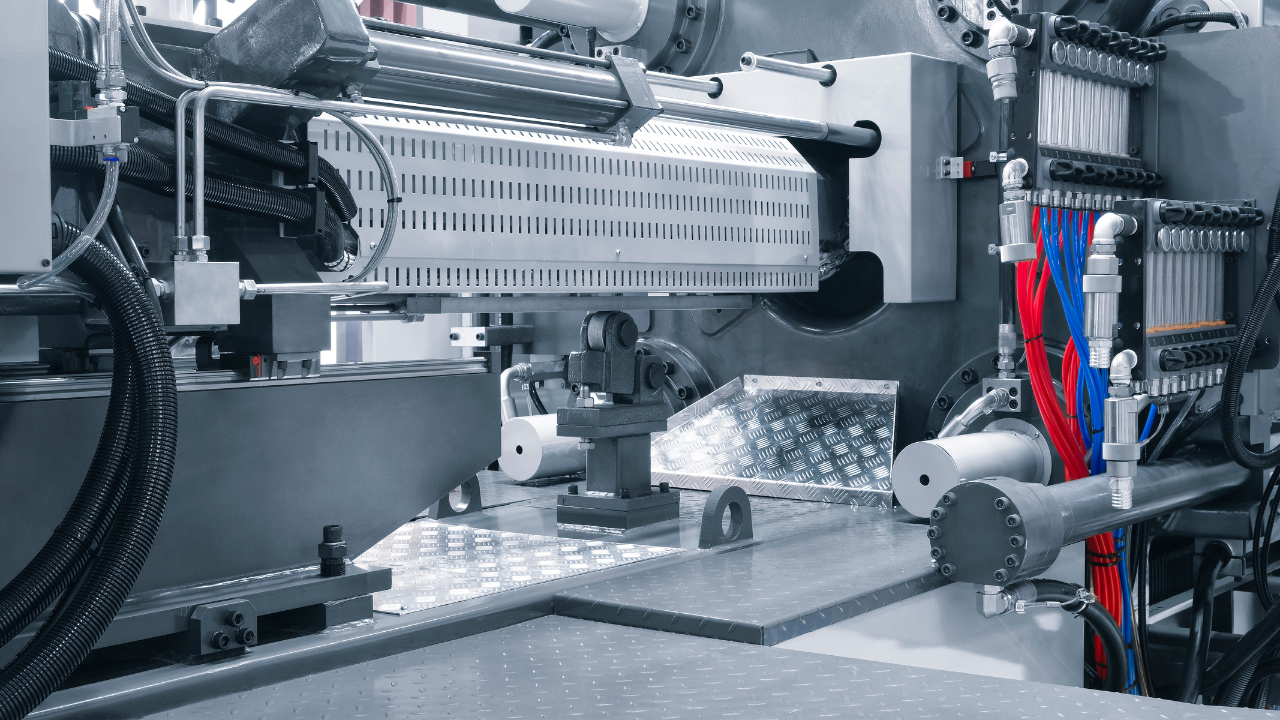

FDI enterprises mainly invest in the production of plastic packaging, technical plastic components, industrial plastics, and recycled plastics for export. A notable trend is the relocation of factories from China to Vietnam to take advantage of lower labor costs and preferential tariffs.

As a result, Vietnam’s plastics industry has not only expanded in size but also significantly improved product quality and competitive capacity.

DRIVING FORCES BEHIND FDI INVESTMENT IN THE PLASTIC INDUSTRY

Several factors are fueling the surge in Vietnam plastic industry FDI investment:

- Investment incentives: The Vietnamese government constantly improves the investment environment, offering tax incentives and industrial infrastructure support.

- Growing consumer market: The rising demand for packaging, plastic materials, and technical components is driven by growth in electronics, food, and healthcare sectors.

- Free trade agreements (EVFTA, RCEP): These agreements open easier access for Vietnamese plastic products to major export markets.

- Supply chain relocation: Many multinational corporations choose Vietnam as their regional manufacturing hub due to competitive costs and strong integration capacity.

At the same time, the adoption of advanced, automated, and energy-saving technologies is becoming critical to enhance production efficiency and meet global standards.

CHALLENGES FOR FDI ENTERPRISES IN PLASTIC MANUFACTURING

Despite its potential, FDI enterprises in the plastics sector face several challenges:

- Rising energy costs: In injection molding processes, mold cooling and temperature control account for up to 60% of total electricity consumption. Operating outdated equipment without flexible power adjustment leads to considerable energy waste.

- Stricter environmental standards: Increasing pressure to meet carbon emission and ESG standards forces manufacturers to invest in energy-efficient technologies.

- Sustaining production performance: Ensuring stable operation and long equipment lifespan is increasingly difficult as production capacity expands.

These challenges highlight the urgent need for advanced cooling solutions that are efficient, intelligent, and environmentally friendly, especially in large-scale injection molding operations.

APPLICATION OF DC INVERTER CHILLER TECHNOLOGY IN PLASTIC MANUFACTURING

In the plastics industry, chiller systems play a critical role in mold cooling, temperature stabilization, and product quality control. As production demand grows, optimizing energy consumption of chiller systems becomes more essential.

DC Inverter chiller technology is a cutting-edge solution increasingly adopted by FDI enterprises thanks to its flexible capacity control, saving 30–40% more energy compared to conventional chillers. The DC Inverter compressor automatically adjusts speed based on actual load, reducing overload during startup and maintaining stable temperature control.

Additionally, DC Inverter chillers help reduce vibration and noise while extending compressor lifespan—an important factor for factories operating continuously. Implementing this technology not only reduces operational costs but also meets the green manufacturing standards pursued by global FDI corporations.

Currently, many Japanese and Korean-invested companies in Vietnam have deployed DC Inverter chiller systems in their injection molding lines, optimizing performance while reducing CO₂ emissions.

DC INVERTER CHILLER SOLUTIONS FROM WHITE COOL

With deep expertise in industrial cooling solutions, White Cool provides a range of DC Inverter chillers specially designed for the plastics industry.

White Cool chillers feature high-efficiency inverter compressors, optimized heat exchangers, and intelligent control systems, significantly reducing energy consumption under all operating conditions.

Notably, White Cool offers ODM-based chiller customization, ensuring each system is tailored to the specific requirements of the FDI manufacturer’s production line. From consulting, design, and installation to maintenance, the White Cool engineering team supports clients to achieve optimal cooling performance and long-term operational value.

CONCLUSION

It is clear that Vietnam plastic industry FDI investment is opening up significant growth opportunities while also imposing increasing pressure on technology, energy efficiency, and environmental compliance. Implementing energy-saving cooling solutions such as DC Inverter chillers not only helps businesses reduce operating costs but also demonstrates their commitment to green and sustainable production.

Contact White Cool today for optimized DC Inverter chiller solutions for your injection molding line — helping your FDI business enhance productivity and meet global standards.